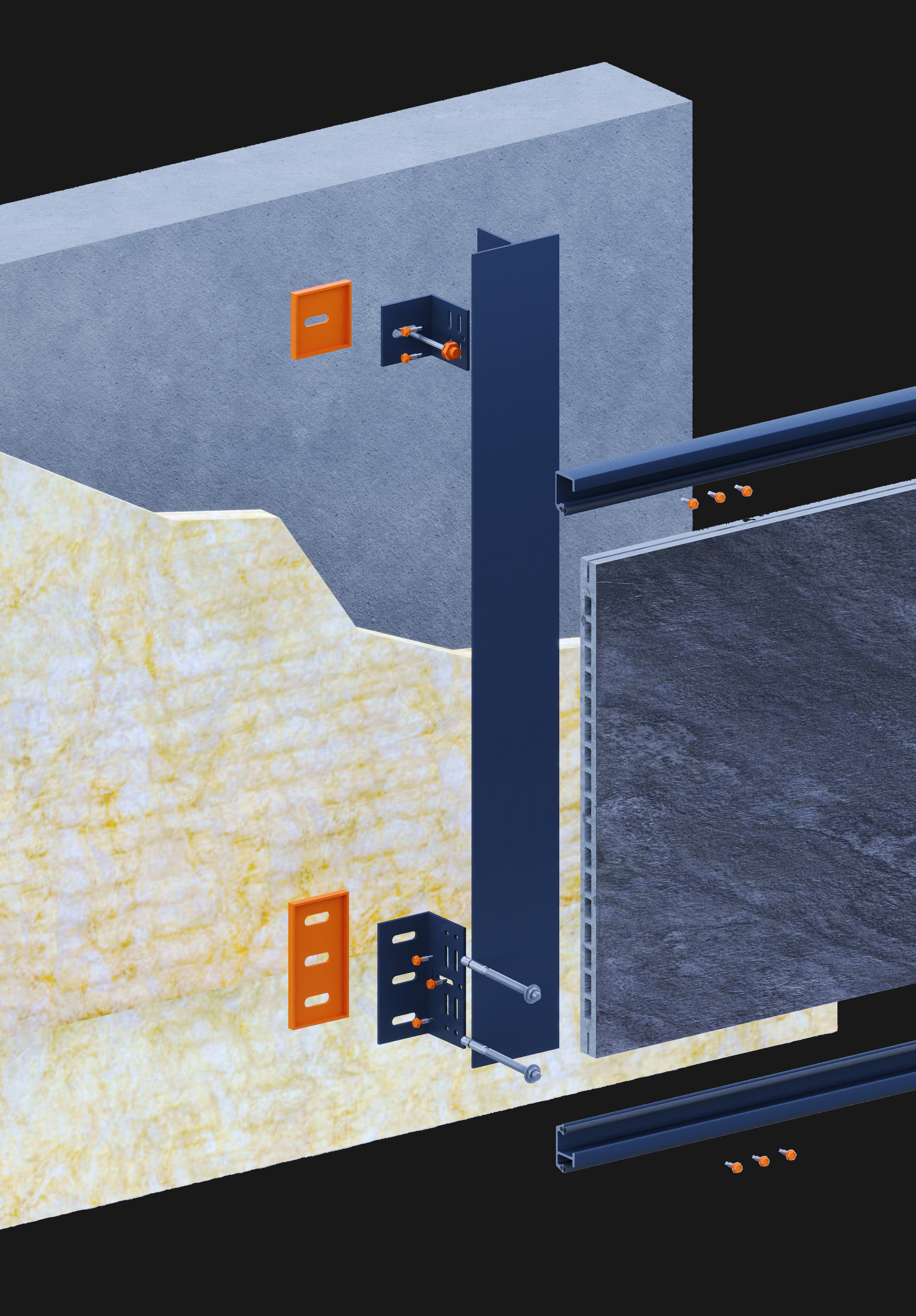

This concealed mechanical system is designed for 20 mm extruded porcelain tiles with factory-formed edge grooves. Tiles are secured via continuous horizontal aluminum profiles and a rear EPDM strip, which cushions against vibrations and allows for system flexibility.Ideal for horizontal tile installations, the system delivers a clean, fastener-free finish with precise alignment. As a dry mechanical method, it eliminates the need for adhesives, reducing environmental impact. Engineered for wind resistance, thermal expansion, and structural stress, it ensures long-term performance and joint stability.

Download Catalog