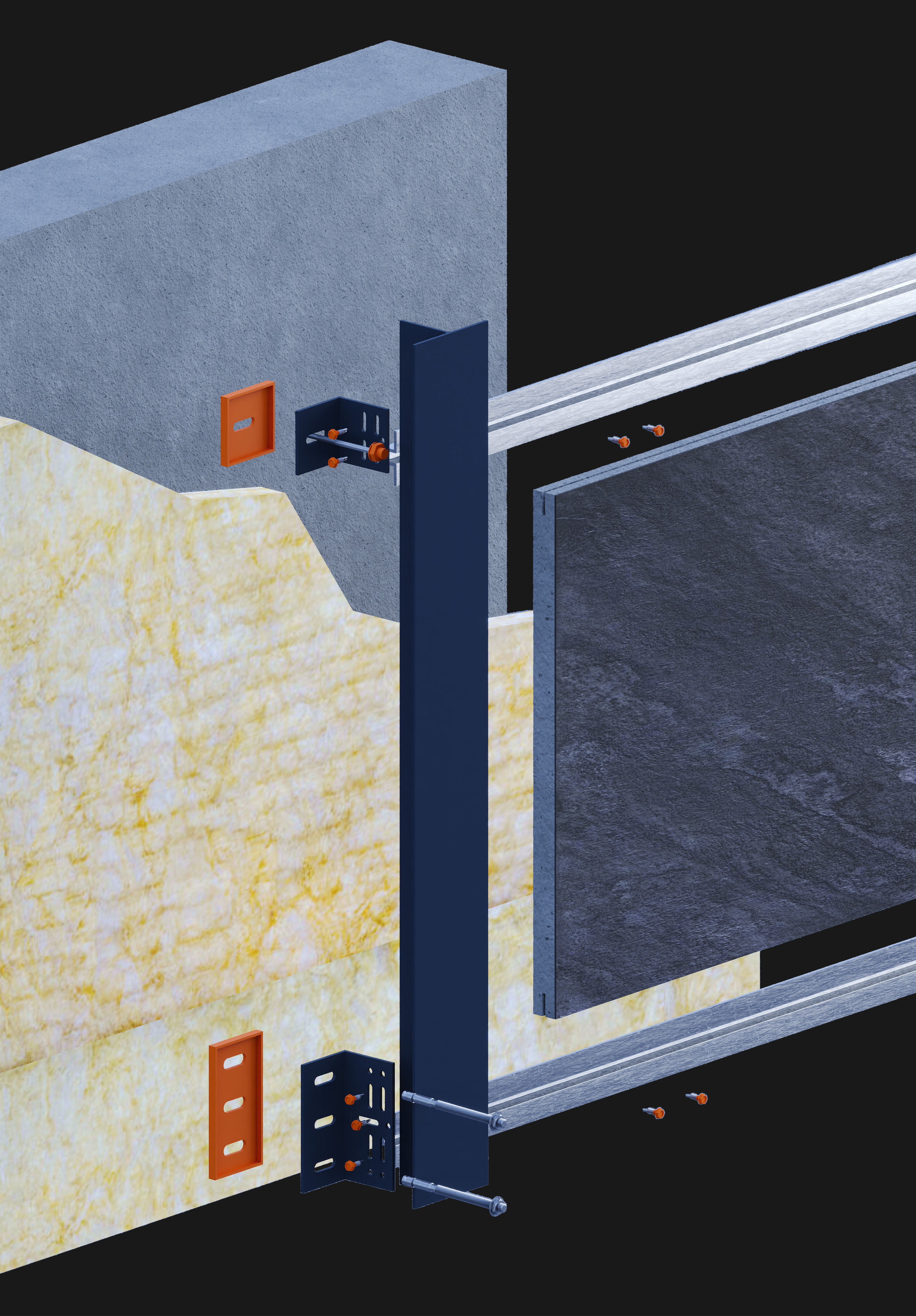

Designed for 12–20 mm porcelain tiles, this concealed fixing system uses continuous horizontal aluminum profiles inserted into full-width kerfs along tile edges. The result is a seamless, fastener-free façade ideal for applications requiring clean lines, structural safety, and long-term durability.The system supports both vertical and horizontal layouts and works with pre-grooved or on-site slotted tiles. Compatible with various substructure configurations, it enables efficient installation and easy tile replacement. As a dry mechanical system, it reduces environmental impact and withstands wind, thermal movement, and structural stress—ensuring lasting alignment and visual uniformity.

Download Catalog