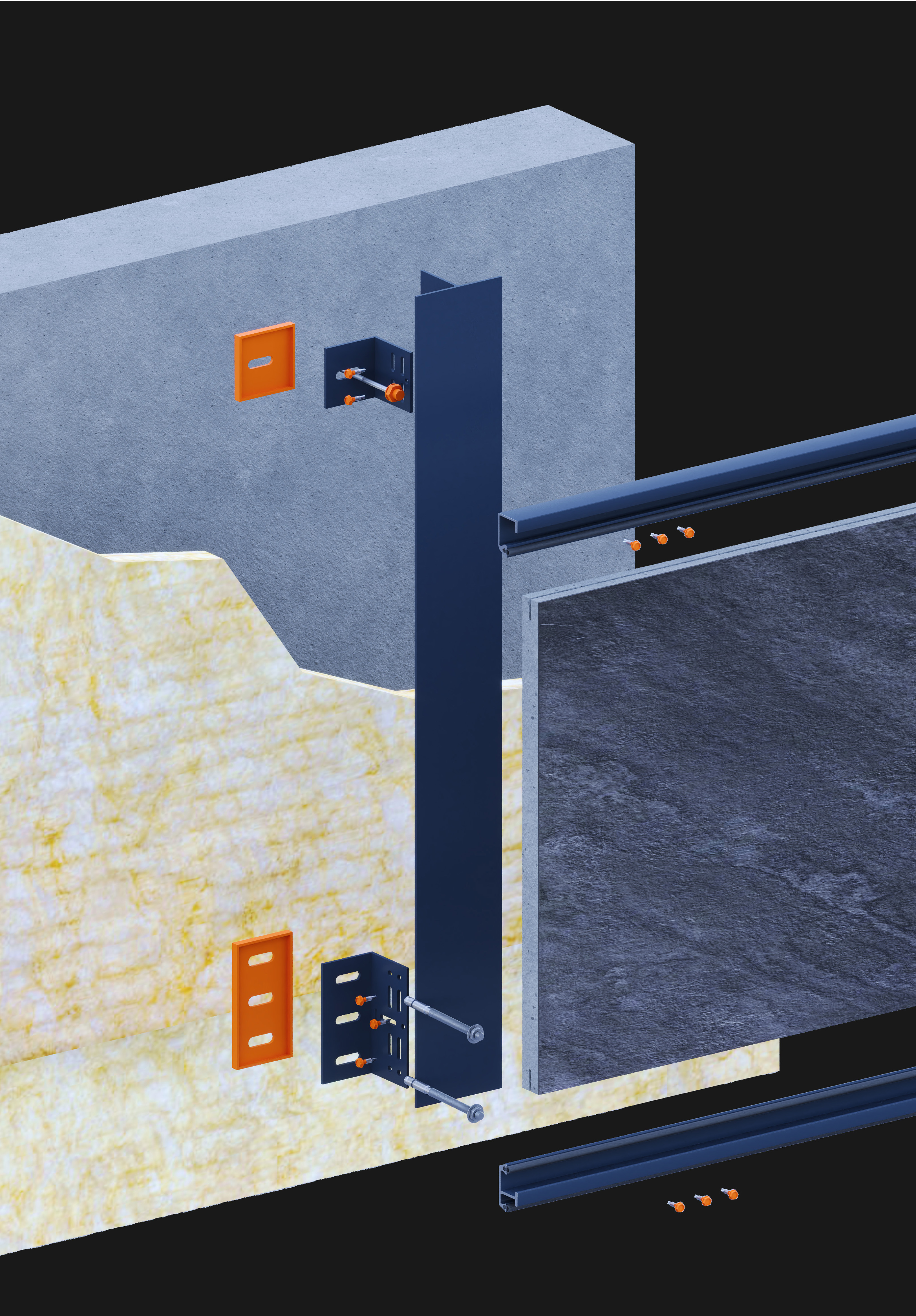

This concealed fixing system is designed for 12–20 mm porcelain tiles with full-width edge grooves, formed either in the factory or on-site. Tiles are secured using horizontal aluminum profiles and a hidden EPDM strip on the rear face to absorb vibration and accommodate minor tolerances.The result is a clean, fastener-free façade surface with strong mechanical engagement and simplified installation. Suitable for both horizontal and vertical layouts, this dry system requires no adhesives, reduces environmental impact, and ensures long-term stability, acoustic comfort, and precise alignment under wind and thermal loads.

Download Catalog